Straw Making Machines Manufacturer

We Manufacture Drinking Straw, PLA & Plastic Straw Making Machines

What Kind Of Straw Do You Want To Produce?

As a professional straw making machine manufacturer, we have a deep understanding of the production and manufacturing processes for both PLA straws and plastic straws, as well as the quality requirements for drinking straws. Regardless of your requirements for straw materials, thickness, or shape, we can customize the straw production machines for you. The pictures below show examples of straws produced by our straw making machines. If you happen to need to produce similar types of straws, just contact us to get the machine information!

Our Straw Making Machine Applications:

1. Food industry: beverage straws, sugar sticks, coffee stir sticks, oral liquid medicine straws, etc.

2. Other industries: signature pen refills, nozzle tubes, balloon sticks, small flag sticks, cotton swab sticks, medical tubes, etc.

Types of Drinking Straw Making Machines

There are various types of drinking straw making machines available in the market today. Some common types include:

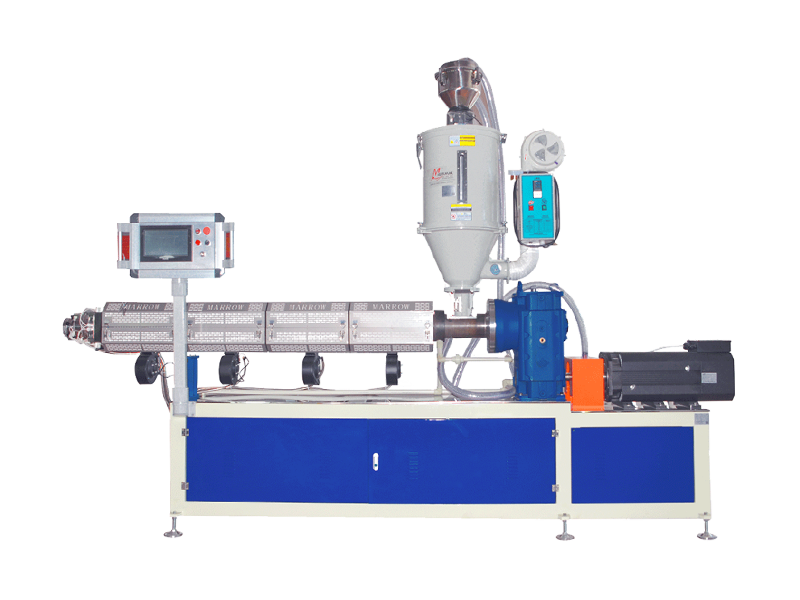

Drinking Straw Extrusion Machine:

It melt plastic resin and shape it into long tubes, which are then cut into individual straw lengths.

PLA Straw Extruder, PLA Straw Making Machines, Biodegradable Straw machine

We have developed specific screws for the production of PLA straws, which enables better mixing of raw materials and result in high-quality PLA straws. If you are interested in our biodegradable straw machine, click the picture or text to learn more about it or just contact us.

PLA Straw Making Machine | |||

Feature | Material | PLA / PP / PE | |

Color | 1 / 2 / 3 | ||

Straw diameter | φ3.0 ~ φ12 mm | ||

Thickness | 0.10 ~ 0.35 mm | ||

Straw length | 80 ~ 300 mm | ||

Stripes | Straight / Helical | ||

Capability | 400 ~ 1800 pcs/min | ||

Extruding output range | 20 ~100 kgs/hr | ||

Extruder | Main Screw diameter | Φ50 / Φ65 mm (BM Screw) | |

Screw L/D | 33 : 1 | ||

Water Cooling Tank | Forming device | 1 set | |

Vacuum Pump Motor | 1.1 kw (choose) | ||

Take up & Cutting Unit | Cutting knife unit | 1 set | |

Angle of port | 90°/60°/45° | ||

Digital counter | 1 set | ||

PHA Straw Making Machine, PHA Straw Extruder

Marrow biodegradable PHA straw making machine is designed with special patented technology, featuring a 65mm/50mm screw and an L/D ratio of 33:1. Please click on the image or text to learn more about the biodegradable PHA straw extruder.

|

PHA/Biodegradable Straw Making Machine |

|||

|

Feature |

Material |

PLA |

|

|

Color |

1 |

||

|

Straw diameter |

φ3.0 ~ φ12 mm |

||

|

Thickness |

0.10 ~ 0.35 mm |

||

|

Straw length |

80 ~ 300 mm |

||

|

Stripes |

Straight / Helical |

||

|

Capability |

400 ~ 1800 pcs/min |

||

|

Extruding output range |

30 ~100 kgs/hr |

||

|

Extruder |

Main Screw diameter |

Φ50 / Φ65 mm (BM Screw) |

|

|

Screw L/D |

33 : 1 |

||

|

Water Cooling Tank |

Forming device |

1 set |

|

|

Vacuum Pump Motor |

1.1 kw (choose) |

||

|

Take up & Cutting Unit |

Cutting knife unit |

1 set |

|

|

Angle of port |

90°/60°/45° |

||

|

Digital counter |

1 set |

||

Plastic Straw Extrusion Machine, Beverage Straw Making Machines

Our plastic straw making machines can produce monochrome, two-color, three-color, and five-color beverage straws. You can click to see more and find additional straw extrusion machines.

|

PP Straw Making Machine |

|||

|

Feature |

Material |

PP / PE |

|

|

Color |

1 / 2 |

||

|

Straw diameter |

φ3.0 ~ φ12 mm |

||

|

Thickness |

0.10 ~ 0.35 mm |

||

|

Straw length |

80 ~ 300 mm |

||

|

Stripes |

Straight / Helical |

||

|

Capability |

400 ~ 1800 pcs/min |

||

|

Extruding output range |

20 ~45 kgs/hr |

||

|

Extruder |

Main Screw diameter |

φ45 mm×2 / Φ50 mm (BM Screw) |

|

|

Screw L/D |

28 : 1 |

||

|

Water Cooling Tank |

Forming device |

1 set |

|

|

Vacuum Pump Motor |

1.1 kw (choose) |

||

|

Take up & Cutting Unit |

Motor |

0.75kW×1(VFD) |

|

|

Cutting knife unit |

1 set |

||

|

Angle of port |

90°/60°/45° |

||

|

Digital counter |

1 set |

||

Drinking Straw Cutting Machine:

Marrow straw making machine can cut different thicknesses of straws and cut them into specific lengths as required.

|

Drinking Straw Cutting Machine |

||

|

Take up & Cutting Unit |

Take up unit |

1 set |

|

Motor |

0.75kW×1(VFD) |

|

|

Cutting knife unit |

1 set |

|

|

Angle of port |

90°/60°/45° |

|

|

Digital counter |

1 set |

|

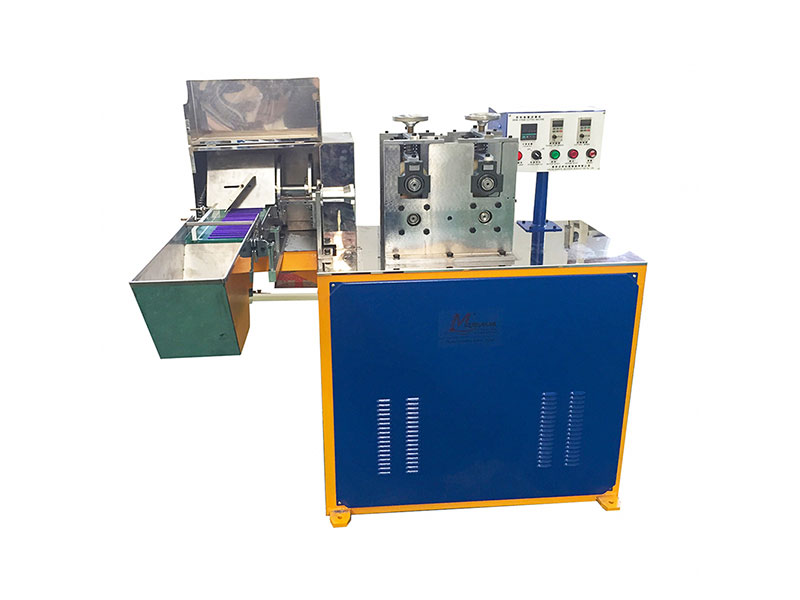

Straw Forming Machine:

Straw shape forming machine can give the straw a specific shape. It can make flexible straws, z-shape straws, telescope tetre-pak straws, spoon straws. etc.

|

Straw Forming Machine |

|||

|

Capability |

250-600 Pieces/minute |

||

|

Automatic counter |

1 set |

||

|

Conveyor |

1 set |

||

|

Specifications of straw | |||

|

Inside Diameter |

Φ3.8mm / 11mm(According to customer requirements) |

||

|

Length of straight straw |

155~260 mm |

||

|

Length of flexible straw |

140~245 mm |

||

|

Thickness of straw |

0.16±0.02 mm / 0.18±0.02 mm / 0.24±0.02 mm |

||

|

Machine weight |

1000 / 1200 / 1500KG |

||

|

Other specifications are customizable |

|||

Straw Packing Machine:

It can be used to package drinking straws of different shapes and quantities.

|

Straw Packing Machine |

||

|

Capability |

350~800pcs/min |

|

|

Wrapping material |

paper, plastic film / BOPP film |

|

|

Width of material |

paper:25~33mm, plastic film:25~60mm |

|

|

Diameter of straw |

Φ4~12mm |

|

|

Length of straw |

150~260mm |

|

|

Other specifications are customizable |

||

Straw Making Auxiliary Equipment:

The entire process of producing drinking straws involves more than just these machines; there are also some auxiliary machines, such as PLA Straw Precipitate Detection System, Automatic Straw Collecting & Finishing Machine, Water Bath, U&i Shape Straw Mege Boxing Machine, Auto Straw Collecting & Conveyor Machine, Filtering Devices, Automatic Sealing Machine, Automatic Palletizing Machine and Automatic Labelling Machine. If you want to learn more about or purchase these machines, click the button below to find the corresponding auxiliary machine for your straw production.

Marrow Machinery Is The Only-One Manufacturer & Supplier of Full Range Of Straw Making Machines In China

Marrow is the only enterprise that can provide a full range of machines required by straw production factories. We enable larger straw factories to realize fully automated production lines.

Automatic Straw Making Machines (Automatic Beverage Straw Production Line)

PLA Straw Making Machines (PLA Drinking Straw Production Line)

As a professional straw making machine manufacturer, we can provide all types of straw making machines required for the production process.

If you have any purchasing needs, please feel free to contact us.

The Benefits of Drinking Straw Making Machines

Drinking straw making machines have significantly increased the production capacity compared to traditional manufacturing methods. These machines can produce a large number of straws in a shorter timeframe, meeting the high demand of straw making industry.

Marrow PLA straw extruder can produce 80kg of straws material per hour, and its production capacity is 400 ~ 1800 pcs/min, with an extrusion output of 60 ~100 kgs/h.

Marrow straw making machines’ automation efficiency is relatively high. Automated straw production eliminates the need for manual labor, resulting in enhanced efficiency and reduced labor costs. Additionally, The data adjustment on the PLC touch screen of the equipment is also very accurate, providing precise data analysis to better address issues that arise during the straw production process. The precise control offered by Marrow machines minimizes material waste, making the straw production process more cost-effective.

Secondly, Marrow straw making machines’ versatility is also a crucial factor in improving production efficiency. During the production process, our straw making machine can adjust parameters such as extrusion speed and temperature based on different production requirements, enabling the production and customization of beverage straws with various specifications and colors.

This multifunctional design significantly enhances the flexibility and production efficiency of drinking straw manufacturing.

Secondly, Marrow straw making machines’ versatility is also a crucial factor in improving production efficiency. During the production process, our straw making machine can adjust parameters such as extrusion speed and temperature based on different production requirements, enabling the production and customization of beverage straws with various specifications and colors.

This multifunctional design significantly enhances the flexibility and production efficiency of drinking straw manufacturing.

All of our products are equipped with the following components: Delta brand variable frequency converters, Schneider circuit breakers, Schneider switches, and rotary knobs. The main motor options include Siemens “Bede” motors or Wan Nan motors. For critical components, we use NSK bearings imported from Japan. As for pneumatic elements, you can choose from “AirTAC” and “SMC” brands.

Learn More About Straw Making Machines

1. The Evolution of Drinking Straws

Drinking straws have been used for centuries, with evidence dating back to ancient times. Initially made from natural materials like reeds or hollowed-out plant stems, straws gradually evolved to include materials such as metal, glass, and paper. However, with the growing need for mass production and cost-effectiveness, the development of drinking straw making machines became essential.

2. The Need for Drinking Straw Making Machines

The surge in demand for drinking straws, especially in the food and beverage industry, created a need for efficient and reliable manufacturing processes. Traditional methods of straw production were labor-intensive, time-consuming, and often resulted in inconsistencies in quality and size. Drinking straw making machines addressed these challenges by automating the production, ensuring uniformity, and significantly reducing production time.

3. Factors to Consider when Choosing a Drinking Straw Making Machine

When selecting a drinking straws machine for your manufacturing needs, several factors should be taken into account:

Production Capacity

Consider the desired production volume to choose a machine that can meet your requirements efficiently. Higher production capacities often come with larger machines and higher costs, so finding the right balance is essential.

Machine Size and Dimensions

Evaluate the available space in your production facility to ensure the machine can be accommodated without hindering other operations. Consider the dimensions, including height, width, and length, of the machine before making a decision.

Customization Options

If you require specialized or unique straw designs, opt for a machine that offers customization options. This allows you to cater to specific customer demands and stand out in the market.

Maintenance and After-sales Support

Ensure that the machine you choose is supported by reliable after-sales service and maintenance. Regular maintenance and timely support will help prolong the lifespan of the machine and prevent downtime.

Quality and Durability and Manufactuerer’s Reputation

Research the reputation of the manufacturer and read customer reviews to ensure the machine is of high quality and built to last.

Price and ROI

Compare the prices of different straw making machines and consider the return on investment (ROI) based on production capacity, material costs, and potential savings in labor and energy.

4. The Future of Drinking Straw Making Machines

Technological Advancements

As technology continues to advance, drinking straw making machines are expected to become more efficient, precise, and versatile. Innovations such as improved automation, advanced control systems, and integration with data analytics are likely to shape the future of this industry.

Sustainability and Environmental Concerns

In recent years, there has been growing concern about the environmental impact of single-use plastic straws. The future of drinking straw making machines will likely focus on making sustainable alternatives, such as biodegradable or reusable straws, to address these concerns and reduce plastic waste.

As a professional straw making manufacturer, we are more than happy to share knowledge about our straw making machines with our customers. We are also eager to assist you in finding the most suitable straw making machine for your beverage straw production needs. If you have any questions or inquiries regarding our straw machines, please don’t hesitate to contact us. We guarantee a response within 24 hours! We are looking forward to hearing from you.